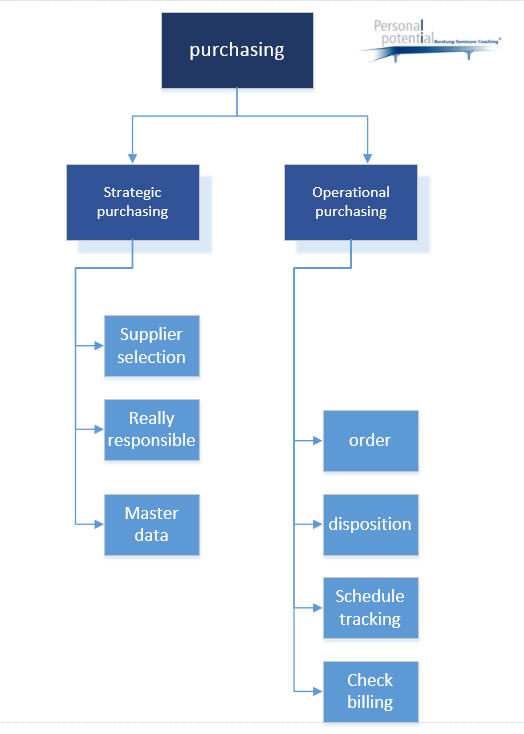

Purchasing in Shopfitting

Purchasing in shopfitting not only means the best possible purchase prices and conditions, but also highest possible standardisation, as the purchase has a direct impact on the Inventory Management and Production. Therefore purchasing activities are often coordinated on an international level.

On the one hand, Purchasing is the acquisition of goods and services (Operative Purchasing) but also the discovery of new suppliers and the negotiation of conditions, as well as the appraisal of the suppliers (supplier audits) (Strategic Purchasing).