Production

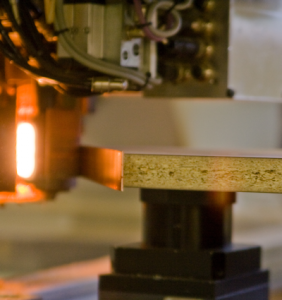

In a modern equipped production plant environmental protection and safety at work are equally important as productivity or product quality. A DP-based network to connect the different jobs with each other will achieve an optimal running time. The data architecture plays a decisive role. Data can be imported to machinery and equipment (e.g. via barcode) and therefore, e.g. set-up times are able to run automated. Facilities in shopfitting often consist of different materials (plastic, glass, wood, metal …). Therefore, there are different processing variations within Production for shopfitting. Hence, the shopfitting industry offers the training of various professions in the manufacturing sector.

Since the versatile products for shopfitting are likely to be created individually for the respective customer, there usually are three product ranges involved in planning, design and production (each depending on the complexity of the respective product.):

Standard Products

are full products or spare parts that are displayed in a price list. These products or spare parts are in their appearance, quality and characteristics offered according to the price list.

Variation

A variation is an article/assembly group which derives from a standard article/assembly group

The following parameters are used here:

1) Pattern variation

2) Proportion variation

3) Function- and facility variation

Individuals

are individual solutions for a product which does not yet exist, or rather which cannot be compound by components of the price list.

A piece of furniture consists of assembly groups, components and separate parts (see image product arrangement).

It is often necessary to adjust the capacities through a flexible working time model to the needs of the customer. Among outstanding quality and productivity this flexibility plays an important role within the shopfitting production.